Industrial revolution summaries

Industrial revolution summaries

The following texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

Industrial revolution summaries

The Beginning of the Industrial Revolution

Starts in Britain: Reasons:

Demand for goods

Need for markets

Skilled laborers (workers) available

Entrepreneurs with capital (money) for investment

Many people needed jobs

Improved agriculture

Enclosure movement

Displaced farmers moved to cities seeking jobs

Natural resources – much coal in England to provide steam, good harbors, iron ore to make machines

Raw materials such as lumber and cotton

Stability of government and economy

Capitalist economy

Gov’t. encouraged science, education, the development of technology; application of science

Textiles

first mechanized industry

“necessity is the mother of invention”

Inventions:

Kay – Flying Shuttle

Hargreaves – Spinning Jenny

Samuel Crompton – spinning mule

Cartwright – power loom

Whitney – Cotton Gin

STEAM

Major source of power

Replaces animal and human labor

1705 – first steam engine

1769‐ Watt perfects the steam engine and makes it more efficient and effective – used to run machines and modes of transportation

“The Age of Steam”

Steam Engine in Transportation

Steamboat: Fulton invented; Clermont –steam driven paddle boat.

Locomotion: Stephenson invented; Rocket (29 miles an hour pulling train cars); led to the development of railroad system

Coal, Iron and Steel

Coal – essential to produce steam

Iron and steel – used to manufacture machines; Bessemer process – refined iron into steel

Steel – basic metal of industrial society

New Sources of Power

Electricity: Faraday – develops electric current; led to development of dynamo – a generator that creates electricity; used today for hydroelectric power; electricity used to run motors, provide light, heat, cooling, transmit signals, sounds and pictures.

Inventors:

Morse – telegraph

Bell – telephone

Edison – electric light bulb

Marconi – wireless telegraph

DeForest – radio vacuum tube

Zworykin – televison

Shockley, Brattain and

Bardeen – transistor

Petroleum – source of power, gasoline, lubrication and lighting

automobile: Daimler – internal combustion engine powered by gasoline; Ford – mass production /assembly line production of cars; HUGE INDUSTRY: making of cars, oil, rubber, steel, glass, aluminum, gas stations, garages, parking lots, motels, highways, roads, repair services

diesel engines‐ Diesel – power heavy machines, buses, trains, autos, locomotives, ships.

Natural Gas ‐ fossil fuel; used in homes for many sources of power

Solar Energy‐ from the sun’s radiation; used for heat and light

Atomic Energy‐ more dangerous source, much contaminated waste; creates a tremendous amount of energy all at

Agricultural Revolution

Early part of Industrial Revolution

Change from primitive methods of farming to the use of machines

Industrial growth encourages improvements in farming: development of labor saving machines,

application of science to increase crop output (production), requiring more agricultural products

such as wool and cotton for goods production, increased food supply needed for growing city

populations

Began in England

Caught on especially fast in the US

Farm Machinery Inventions

Jethro Tull – Seed drill

Newbold – cast-iron plow

McCormick- reaper

Deere – self-cleaning steel plow

additional inventions- thresher, harvester, tractor, electric milker, cotton picker, potato digger.

Scientific Agriculture

Townshend – rotation of crops

Blakewell – scientific breeding

von Liebig- artificial fertilizers

George Washington Carver – many uses for peanuts – major crop in the Am. South –major source of revenue

application of science: contour plowing, ways to prevent soil erosion, drainage systems, irrigation, insecticide, fertilizers, canning, refrigeration, freezing foods.

Effects of Agricultural Revolution

increased agricultural production

decreased cost of foodstuffs

small farms declined and gave way to big farms – plantations – could use machines and scientific methods more effectively

less farmers needed – many move to the cities looking for jobs: urbanization

farming required less physical labor

farming changes from being self-sufficient to big business

Industrial Revolution by Country Summary

Britain: becomes far more industrial than agricultural; first industrialized nation; produces mostly textile items; “workshop of the world”; faces many problems today – running out of coal, outdated machinery and factories, stiff competition from other countries.

United States: Samuel Slater – British immigrant to America- memorized the design of machines and factories so they could be built in America; textiles first big industry; major revolution in industry immediately following the Civil War; US has many natural resources, available capital, good transportation, communication (infrastructure), gov’t. pro-business supply of capable workers, many inventors and enterprising individuals; Rockefeller and Andrew Carnegie are examples of major business magnates; struggling against Japan and Germany to remain a major industrial power.

France: limited industry; mostly handicraft labor and luxury items (wine, lace, silk, perfume, jewelry); lacked political stability and sufficient resources to start and sustain industrialization; most people preferred farm life and did not want to work in factories; since WW II – increased production of cars, steel, airplanes.

Germany: industrialized rapidly; v. good coal and iron resources, skilled workers, v. good education, gov’t. support, talented scientists, good water systems and transportation, many huge companies began industrial leaders (Krupps, Mercedes Benz, Bruen); major leaders in precision instruments and chemical industries; heavy industry – steel, iron, etc. A major leading industrial power in the world today.

Russia (Soviet Union): did not begin much industrialization before 1914, lags behind the rest of the world; Soviets try to push industrialization – too fast and not successfully; some gains made but has been on a down-slide since 1980’s; struggling today to form a free market economy

Japan: threatened with foreign domination, Japan industrialized rapidly to avoid it; first Asian nation to industrialize; lacked resources and farmland but had cheap labor, government assistance and many near Far Eastern markets; major producer of technical items – cameras, computers, electronics, machinery, automobiles; today a very major industrial power.

Developing countries – most of Asia, Africa and Latin America – still mainly primitive agricultural economies – self-sufficient farming; lack of gov’t. stability, capital, skilled labor and technical “know how” hold them back from industrializing.

The Consolidation of the Industrial Order, 1850-1914

Infrastructure gradually improves

Railroads, canals, urbanization

Britain – 50% live in cities – first time in human history

Handle city problems

Sanitation, parks, regulation of food/housing facilities

Crime rates drop/stabilize

Adjustments to Industrial Life

Family life changes

Low birth rates/low death rates – kids more important – not source of income

Better health for kids – only 10% are dying before 10 years old – yippee!

Louis Pasteur discovers germs – better health/sanitation

Consumer culture begins

More money to buy products – living above subsistence

Rise in corporations

more stock owned companies

labor unions created

workers bargain for better pay/conditions’

Farmer life improves

More connected

Developed staple crops

Cooperatives to market crops/purchase supplies – can be done cheaper if work together

Source : http://psychedout.wikispaces.com/file/view/Industrial+Revolution.docx

Web site link: http://psychedout.wikispaces.com

Google key word : Industrial revolution summaries file type : doc

Author : not indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly.

Industrial revolution summaries

Industrial Revolution Review Guide

Industrial Revolution

- a major change in a country’s method of producing goods and organizing labor

- a movement from:

- an agricultural to an industrial society

- manual labor to use of machines

- Rural society to an urban society

Characteristics of Pre-Industrial Society

- most people lived and worked on farms

- wealthy nobles controlled the land

- agricultural methods had not changed drastically for centuries

- people rarely travelled

- Inefficient methods were used to plant and harvest crops

- communication between towns and cities was slow and infrequent

- people supplemented their income by mining their land, working out of their homes

- infant mortality high

- life expectancy short

Domestic System (Cottage Industry)

- Early industrial labor system in which people produced goods in their homes

- Textiles, Coal

- Workers typically completed a step of the manufacturing process in their homes and then passed their portion onto another home for the next step (Spinner, weaver, fuller, dryer)

- Benefits

- Workers set own hours

- Women cared for their children, completed domestic duties

- Children worked along side their parents

- Provided income during hard times

Industrial Revolution

- Began – England

- 1750-1900s

- Textile Industry

Why England?

- Enclosure Movement - Wealthy landowners ended open field system to increase efficiency and productivity

- New Agricultural improvements

- New inventions/discoveries

- Crop rotation – used turnips to enrich the soil

- Seed Drill (Jethro Tull) – reduced seed waste

- Selective Breeding (Bakewell) – used only strongest and healthiest animals for breeding

- Results

- Improved the quantity, quality, and profitability of food

- Increased lifespan and infant mortality rates

- Small farmers forced off of farms to towns and cities to find work

- Good Labor Supply – large number of able workers

- Birthrates increased & death rates decreased

- Many workers were skilled and educated

- Natural resources – coal, iron ore, waterways, resources from colonies (wool, cotton)

- Investment capital – available money

- Wealthy landowners and merchants

- Strong banking system

- Entrepreneur

- Markets

- Colonies provided markets to sell finished goods

- New jobs and wealth created a cycle of new markets (more $ made = more money to spend)

- Large demand for textiles (demand exceeded supply)

- Government support

- Laws to protect businesses

- Patent laws encourage investment

- No internal tariffs

- Political stability – long standing constitutional monarchy

- Mobile Society – ability to move up in society

- No rigid class system

- Work ethic admired

Textiles – cloth

- Domestic system can’t meet rising demand for cotton

- New technologies invented to meet demand

Textile Industry Inventions

Invention |

Inventor |

Impact |

Flying Shuttle |

John Kay |

Faster weaving |

Spinning Jenny |

James Hargreaves |

Faster Spinning |

Water Frame |

Richard Arkwright |

Spinning machine running on waterpower |

Spinning Mule |

Samuel Crompton |

Produced stronger thread |

Power Loom |

Edmund Cartwright |

Faster weaving running on water or steam power |

Cotton Gin |

Eli Whitney |

Cleaned Cotton 50X faster |

Industrial Developments and Other Inventions

Invention |

Inventor |

Impact |

*Steam Engine |

James Watt |

Factories could run continuously away from water |

*Steel |

Henry Bessemer |

Answered industry’s need for a sturdy, workable metal |

Steam Boat |

Robert Fulton |

Fast and inexpensive way to transport goods. |

Telegraph |

Samuel Morse |

Using a system of dots and dashes it carried information at high speeds |

Radio |

Guglielmo Marconi |

First invented as the wireless telegraph |

Telephone |

A.G. Bell |

Revolutionized communication |

Electric Generator |

Richard Trevithick |

Made global economy possible |

Phonograph |

Thomas Edison |

Produced sound, |

Light bulb |

Thomas Edison |

Made Electric lighting inexpensive/accessible |

Oil Burning Internal- Combustion Engine |

G. Daimler |

Power for industry, RR, cars |

Airplane |

Wright Bros. |

Revolutionized Transportation |

*Steam Power and Steel made major contributions to the Industrial Revolution

Steam Power:

- Cloth and other products were produced more efficiently

- Cost of producing textiles and other products was greatly reduced

- Put hand producers out of business

- Factories could be run continuously

- Factories could be built anywhere

Spread of Industrial Revolution

- Wealthy industrialist spread the Industrial Revolution to other countries for profit

- Railroads and factories were built in the Colonies

- France, Germany and US (Samuel Slater) follow

- By 1870 US ranks with England and Germany as one of 3 most industrial counties in the world

Factory System** |

Domestic System* |

Machine made |

Hand made |

Lower price |

Higher price |

Fewer Workers for same job |

More workers for same job |

Work in Factory |

Work at home |

Faster, More efficient |

Slower, takes more time |

Identical Products |

Unique Products |

Work on a schedule |

Set your own hours |

Mass production |

Limited production |

Larger markets |

Limited markets |

Specialized Tasks/Assembly line |

Control all aspects of production |

Increase in Quantity |

Lower product output |

*Domestic System – method of production in which goods were produced at home in a step process

**Factory System – method of production in which a finished product is made by workers and machines in one location (a factory) outside their homes

Factory Terms:

Mass Production – producing huge quantities of identical goods

Division of Labor (Fredrick Taylor) – specialized tasks in a step-by step process

Interchangeable Parts – machine made, identical, easily assembled and exchanged

Assembly Line (Henry Ford) – implementation of specialized tasks along a factory line

A New Society

1. Rising Middle Class – a growing wealthy class of industrialists, business owners, and overseers

- Men work, women stay home – new men and women stereotypes emerge

- Hired domestic help to help with women’s domestic chores

- Boys went to school

- Girls prepared for marriage

2. Growth of Urban Poor

- Once small rural farmers

- Depended on factory work for livelihood

- No longer made or grew what families need

- Lost jobs as competition for factory jobs grew

3. Working Conditions

- Worked 10-14 hr. days

- Low wages

- Men, women and children worked

- Dangerous Conditions - unventilated rooms, cramped work spaces, heavy machinery, dust and filth, few breaks, severe punishments

4. Women Workers

- Worked in factories, mines, as domestic servants

- Mill girls – single girls worked in mill towns away from families

- Spent long hours away from children

- Housework after 12-14 hour work days

- Hazardous working conditions

- Paid 50% of male wages

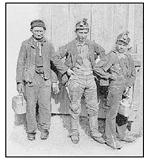

5. Children Workers

- No longer worked along side parents

- Started as early as 6 yrs old

- Paid 10% of male wages

- Few breaks

- Dangerous work – deformed bodies, lost limbs, long-term illness, sever punishments

5. Urbanization

- 5 out of 10 English lived in the city

- Housing – dark, poorly constructed, badly ventilated, cramped

- Unsanitary conditions – no garbage removal, in-door plumbing

- Disease spread

- Crime increased

Labor Unions – group of workers formed to pressure business owners to improve wages and working conditions

- Sit-ins – workers stopped working, refusing to leave to demonstrate dissatisfaction

- Walk-out – stopped working at a specific time and walked out

- Strikes – workers refused to return until demands were met

- Collective Bargaining – both sides meet to negotiate a compromise

- Slow downs – workers purposefully slow down production

Source : http://www.solonschools.org/accounts/rjoseph/IndustrialRevolutionStudyGuide.doc

Web site link: http://www.solonschools.org

Google key word : Industrial revolution summaries file type : doc

Author : not indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly.

Industrial revolution summaries

INDUSTRIAL REVOLUTION

*The application of power-driven machinery to manufacturing

Began in England 1700-1800s, good labor force and raw materials (large population and cotton from the colonies)

*Agricultural Revolution

-Enclosures- farmers sectioned off land w/ fences or hedges

-Crop rotation- growing different crops in fields to preserve soil-wheat, turnips, oats, barley, clover

-Innovations- Jethro Tull- seed drill, Robert Blackwell- stock breeding livestock, John Deere-steel tip plow, Eli Whitney- cotton gin, Cyrus McCormick- reaper

-More food- more people- more efficient farms- urban growth

*Transportation Improvements

Fossil fuel revolution- coal

-James Watt- the steam engine

-Robert Fulton- the steam ship, the Claremont- 1st steamboat carried passengers on the Hudson R. in NY

-George Stephenson- developed the 1st railroad line (27 miles), “The Rocket”- steam locomotive that traveled at 24 mph

-Ships and trains could carry raw materials and manufactured goods quickly and cheaply.

-Road improvements- more roads w/ drainage for wet conditions

Early Factory

Jethro Tull’s seed drill

Jethro Tull’s seed drill

John Deere Eli Whitney’s cotton gin

Steam engine

Steam engine

Robert Fulton’s Claremont steamboat

The Rocket

The Rocket

*Technological Change

-Matthew Boulton- est. the 1st factory (1762), a wood working factory w/ 600 workers, two water wheels, a steam engine

-The Flying Shuttle (1733) a piece of wood w/ yarn attached ran back & forth to make cloth, doubled production invented by John Kay

-The Spinning Jenny (1778) spin multiple threads at once, invented by James Hargraves

*Changes in Lifestyles

-Urbanization- people moved to the cities to find jobs in the new factories, city populations grew outrageously, some countries doubled population

-Slums- city builders could not keep up w/ population growth, low income families moved to the outskirts of the cities where they lived in poor sanitation, disease (cholera), overcrowding (40/room)

-Working Conditions- 14 hr. days, 6 days/wk, dangerous conditions, poor lighting, coal mines very dangerous, many children worked

Matthew Bolton

Matthew Bolton

The Flying Shuttle The Spinning Jenny

Overcrowded cities Cholera epidemic

Mill conditions

Mill conditions

Laundry in the streets

Laundry in the streets

Industrialization in the us

US had good resources (coal, iron ore), workers, land and rivers

*1st factory- built by Samuel Slater and Moses Brown- textiles

*Francis Cabot Lowell- textiles in New England, Lowell, Mass b/cm a booming mill town, “mill girls”- came from rural areas & worked 12 hr. days 6 days/wk.

*Shoes- big industry- New England

*Railroad- grew from 3,000 mi. of track to 200,000 mi. in 50 years, by 1869 Transcontinental Railroad

*New inventions- Samuel Morse-telegraph, Thomas Edison- light bulb, Alexander Graham Bell- telephone, George Washington Carver- 300 uses for the peanut

*The Corporation- to raise money companies sold stock- stockholders would own part of the corporation & share the profits- but not responsible for debts.

Andrew Carnegie- Carnegie Steel

John D. Rockefeller- Standard Oil

Cornelius Vanderbilt- shipping & RR

Industrialization in other countries-

*Belgium- had iron, coal & waterways- led to steam engines, machinery & trains

*Germany- had coal, iron good rivers led to steel mills, machinery, textiles, built extensive RR lines, also b/cm a large military threat

*Italy- waterways, textiles, silks

“Have and Have-Nots”- the world changed to a global economy; countries that failed to industrialize were left behind and suffered

US coal miners

US coal miners

Francis Cabot Lowell “Mill Girls”

Samuel Morse Thomas Edison

Alexander Graham Bell George Washington Carver

Carnegie Steel Works

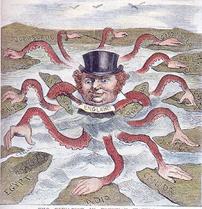

Standard Oil

Standard Oil

Economic systems

New economic systems and economic thought developed.

*Adam Smith- professor Univ. of Glasgow, Scotland- wrote Wealth of Nations. He argued for a “free” economic system- “laissez faire”- an economy w/o govt. interference

*Capitalism

aka “Free-enterprise” system- economic system based on private ownership, profit motive, competition, supply and demand.

Loose govt. regulations, like the US

Criticism is exploited poor class

*Socialism

Ideas behind socialism

-Jeremy Bentham- introduced “Utilitarianism” philosophy- govt. should act for the benefit for the greatest number of people

-Thomas More- Utopia- ideal place w/ no poor

Socialists believe the means of production (factories, land, materials, etc.) are owned by the public and operate for the public, govt. controls everything

*Communism

-Karl Marx, German philosopher, wrote “The Communist Manifesto” w/ Friedrich Engels, friend & philosopher

Communism was an economic plan to help the proletariat- the working class, Marx predicted a workers’ revolution, Marx argued for govt. control of everything for the benefit of the public, everyone would share equally

Communist govt.- Russia(1917), China(1930’s), Cuba(1959)

Adam Smith

Adam Smith

Jeremy Bentham Thomas More

Karl Marx and Friedrich Engels

Communist party

Effects of the Industrial Revolution

*Unionization- labor unions formed for worker’s rights (better pay, better hours, improved working conditions, benefits)

-Strike- refusal to work

-Collective bargaining- negotiations  b/t the workers and management

b/t the workers and management

AFL- American Federation of Labor- several unions combined, powerful

*New laws- child labor laws- limiting hours (Ten Hours Act of 1847) and certain jobs (not allowed in mines)

*End of slavery- US Civil War- 1865

*Women’s Rights- women’s unions,

Jane Addams- est. Hull House, a boarding house for working women in Chicago, spread to other cities

*The New Middle Class- merchants and factory owners b/cm rich exploiting workers, middle class now included skilled workers, govt. workers, doctors, lawyers, managers. The middle class b/cm the dominant class.

*Education reform- Horace Mann- free education all US children

*Imperialism- countries extended their rule over a less powerful country, new markets and raw materials

US labor union

US labor union

“Bread and Roses” Strike 1912

Jane Addams Horace Mann

Hull House

Hull House

Imperialism

Imperialism

Source : http://worldhistory-dease.wikispaces.com/file/view/INDUSTRIAL+REVOLUTION-+notes.doc/280664590/INDUSTRIAL%20REVOLUTION-%20notes.doc

Web site link: http://worldhistory-dease.wikispaces.com/

Google key word : Industrial revolution summaries file type : doc

Author : not indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly.

Industrial revolution summaries

Industrial Revolution in America

During the early 1800s, the Industrial Revolution dramatically changed the American way of life.

Setting the Scene

At dawn, the factory bell woke eleven-year-old Lucy Larcom. Rising quickly, she ate her breakfast and hurried to her job at a spinning mill in Lowell, Massachusetts. Years later, Larcom described her workplace:

"The buzzing and hissing and whizzing of pulleys and rollers and spindles and flyers around me often grew tiresome. . .I could look across the room and see girls moving backward and forward among the spinning frames, sometimes stooping, sometimes reaching up their arms, as their work required. "

In the early 1800s, busy factories and whirring machinery had become part of a revolution that was reaching the United States. Unlike the American Revolution, this one had no battles or fixed dates. The new revolution - the Industrial Revolution - was a long, slow process that completely changed the way in which goods were produced.

The Industrial Revolution Begins

Before the 1800’s, most Americans were farmers and most goods were produced by hand. As a result of the Industrial Revolution, this situation slowly changed. Machines replaced hand tools. New sources of power, such as steam, replaced human and animal power. While most Americans continued to farm for a living, the economy began a gradual shift toward manufacturing.

New Technology

The Industrial Revolution started in Britain in the mid-1700s. British inventors developed new machines that transformed the textile industry. Since the Middle Ages, workers had used spinning wheels to make thread. A spinning wheel, however, could spin only one thread at a time. In 1764, James Hargreaves developed the spinning jenny, a machine that could spin several threads at once. Other inventions sped up the process of weaving thread into cloth. In the 1780s, Edmund Cartwright built a loom powered by water. It allowed a worker to produce a great deal more cloth in a day than was possible before.

The Factory System

New inventions led to a new system of producing goods. Before the Industrial Revolution, most spinning and weaving took place in the home. Large machines however, had to be housed in large mills near rivers. Water flowing downstream or over a waterfall turned a wheel that produced the power to run the machines.

To set up and operate a spinning mill required large amounts of capital, or money. Capitalists supplied this money. A capitalist is a person who invests in a business in order to make a profit. Capitalists built factories and hired workers to run the machines.

The new factory system brought workers and machinery together in one place to produce goods. Factory workers earned daily or weekly wages. They had to work a set number of hours each day.

A Revolution Crosses the Atlantic:

Britain wanted to keep its new technology secret. It did not want rival nations to copy the new machines. Therefore, the British Parliament passed a law forbidding anyone to take plans of the new machinery out of the country.

Slater Breaks the Law

Samuel Slater soon proved that this law could not be enforced. Slater was a skilled mechanic in a British textile mill. When he heard that Americans were offering large rewards for plans of British factories, he decided to leave Britain in 1789. Slater boarded a ship bound for New York City. He knew that British officials searched the baggage of passengers sailing to the United States. To avoid getting caught, he memorized the design of the machines in the mill.

The First American Mill

Slater soon visited Moses Brown, a Quaker capitalist who had a mill in Pawtucket, Rhode Island. The mill was not doing well because its machinery constantly broke down. Slater set to work on improving the machinery. By 1793, in Pawtucket, he built what became the first successful textile mill in the United States that was powered by water. Slater's wife, Hannah Slater, contributed to the success of the mill. She discovered how to make thread stronger so that it would not snap on the spindles.

Slater's factory was a huge success. Before long, other American manufacturers began using his ideas.

Interchangeable Parts

American manufacturers benefited from the pioneering work of American inventor Eli Whitney. Earlier, skilled workers made goods by hand. For example, gunsmiths spent days making the barrel, stock, and trigger for a single musket. Because the parts were handmade, each musket differed a bit from every other musket. If a part broke, a gunsmith had to make a new part to fit that particular gun.

Whitney wanted to speed up the making of guns by having machines manufacture each part. All machine-made parts would be alike-for example, one trigger would be identical to another. Interchangeable parts would save time and money.

Because the government bought many guns, Whitney went to Washington, D.C., to try to sell his idea. At first, officials laughed at his plan. Carefully, Whitney sorted parts for 10 muskets into separate piles. He then asked an official to choose one part from each pile. In minutes, the first musket was assembled. Whitney repeated the process until 10 muskets were complete.

The idea of interchangeable parts spread rapidly. Inventors designed machines to produce interchangeable parts for clocks, locks, and many other goods. With such machines, small workshops grew into factories.

Lowell, Massachusetts: A Model Factory Town

The War of 1812 provided a boost to American industries. The British blockade cut Americans off from their supply of foreign goods. As a result, they had to produce more goods themselves.

The Lowell Mills

During the war, Francis Cabot Lowell, a Boston merchant, found a way to improve on British textile mills. In Britain, one factory spun thread and a second factory wove it into cloth. Why not, Lowell wondered, combine spinning and weaving under one roof? The new mill that he built in Waltham, Massachusetts, had all the machines needed to turn raw cotton into finished cloth.

After Lowell's death, his partners took on an even bigger project. They built an entire factory town and named it after him. In 1821, Lowell, Massachusetts, was a village of five farm families. By 1836, it boasted more than 10,000 people. Visitors to Lowell described it as a model community composed of "small wooden houses, painted white, with green blinds, very neat, very snug, [and] very nicely carpeted."

Work in the textile mills in the early 1800s was hard. Workers faced long hours on their feet amid the noisy machines. Yet, the mills were generally clean and orderly.

"Lowell Girls"

To work in their new mills, the company hired young women from nearby farms. The Lowell girls, as they came to be called, usually worked for a few years in the mills before returning home to marry. Most sent their wages home to their families.

At first, parents hesitated to let their daughters work in the mills. To reassure parents, the company built boardinghouses. The company also made rules to protect the young women.

Although factory work was often tedious and hard, many women valued the economic freedom they got from working in the mills. One worker wrote her sister Sarah back on a farm in New Hampshire:

"Since I have wrote you, another pay day has come around. I earned 14 dollars and a half. . . I like it well as ever and Sarah don't I feel independent of everyone! "

Daily Life During the Industrial Revolution

In Lowell and elsewhere, mill owners hired mostly women and children. They did this because they could pay women and children half of what they would have had to pay men.

Child Labor

Boys and girls as young as seven worked in factories. Small children were especially useful in textile mills because they could squeeze around the large machines to change spindles.

Today, most Americans look upon child labor as cruel. Yet in the 1800s, farm children also worked hard. Most people did not see much difference between children working in a factory or on a farm. Often, a child's wages were needed to help support the family.

Long Hours

Working hours in the mills were long - 12 hours a day, 6 days a week. True, farmers also put in long hours. However, farmers worked shorter hours in winter. Mill workers, in contrast, worked nearly the same hours all year round.

In the early 1800’s, conditions in American mills were generally much better than in most factories in Europe. As industries grew, however, competition increased and employers took less interest in the welfare of their workers. Later on you will read how working conditions grew worse.

Changes in Home Life

The Industrial Revolution had a great impact on home life. As the factory system spread, more family members left the home to earn a living.

These changes affected ideas about the role of women. In poorer families, women often had to go out to work. In wealthier families, husbands supported the family while wives stayed at home. For many husbands, having a wife who stayed at home became a sign of success.

Growing Cities

In 1800, the vast majority of Americans lived in rural areas. During the Industrial Revolution, many people left farms to work in factories. Older cities expanded rapidly, while new cities sprang up around factories. This movement of the population from farms to cities is called urbanization.

Urbanization was a steady but gradual process. In 1800, only 6 percent of the nation's population lived in urban areas. By 1850, the number had risen to 15 percent. Not until 1920 did more Americans live in cities than on farms.

By today's standards, these early cities were small. A person could walk from one end of any American city to the other in as little as 30 minutes. Buildings were only a few stories tall. As the factory system spread, the nation's cities grew.

Hazards

Growing cities had many problems. Dirt and gravel streets turned into mud holes when it rained. Cities had no sewers, and people threw garbage into the streets. A visitor to New York reported that "The streets are filthy, and the stranger is not a little surprised to meet the hogs walking about in them, for the purpose of devouring the vegetables and trash thrown into the gutter." Under these conditions, disease spread easily. Epidemics of influenza and cholera raged through cities, killing hundreds.

Attractions

Cities had attractions, too. Theaters, museums, and circuses created an air of excitement. In cities, people could shop in fine stores that sold the latest fashions from Europe. Some offered modern "ready-to-wear" clothing. While most women continued to sew their own clothes, many enjoyed visiting hat shops, china shops, shoe stores, and "fancy-goods" stores.

Source : http://www.stowe.k12.vt.us/sms/teachers/sbuzzell/documents/IndustrialRevolutioninAmerica.doc

Web site link: http://www.stowe.k12.vt.us

Google key word : Industrial revolution summaries file type : doc

Author : not indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly.

Industrial revolution summaries

If you want to quickly find the pages about a particular topic as Industrial revolution summaries use the following search engine:

Industrial revolution summaries

Please visit our home page

Larapedia.com Terms of service and privacy page